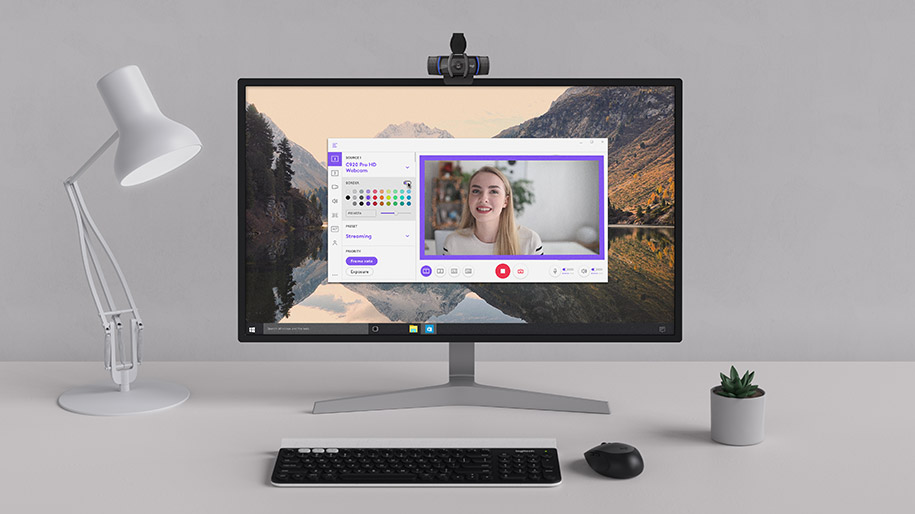

Logitech Video Cams

- now becoming available again.

A year, or maybe 18 months ago, we bought a computer video camera / mic to make high-res / good audio quality videos so we could explain some of our services. We did some research at the time, reading reviews, checking spec's, price shopping and so on to find a camera with better quality than the little black spot on top of the screen of our laptop computers could provide. We bought a Logitech 1080p model for well under $100. After Feb/March of this year the use of remote video conference devices went ballistic, and the prices demanded for higher quality web cams skyrocketed as well. We were surprised to learn our little web cam that perches on top of a computer monitor now commands nearly $250 a copy, and now similar units made by brands we do not recall from our earlier research are priced nearly as high. What's going on here? Is this price gouging caused by the virus panic? 1080 / 720

That's the resolution everyone wants, 1080 or 720 lines or pixels. This level is generally considered to be HD, or high definition. Many of the older built-in cams on laptops, tablets or phones are 480 or in that range ( 450 to 540 ), or an approximation of the old standard definition TV resolution. The CCD's (charge coupled devices), the things that acually sense the light / photons and turn them into electrons (roughly a kind of electronic film ) and lenses of these cams were built to a spec similar to the 480 line / pixel spec, far below the image quality of the HD spec. Suddenly everyone is going to work via a web cam. People who have never done this before, who have only a desktop computer and a smart phone at home, suddenly need to dress up (at least from the waist up) so they can look presentable, and not look like a re-run of an old TV show from the 1960's / 1970's etc. So they're out snapping up each and every device that can be found which looks like it will perch on their computer monitor and deliver a high definition picture to the next Zoom meeting.Manufacturing lead times.

Some years ago, when this Burdette law firm staffer was involved in electronics manufacturing stateside and on the far side of the Pacific, we tried to design as many of our products as possible using the same parts. The price of electronics parts is very volume sensitive. Even with parts priced in fractions of a cent, a lot of money could be saved for the company that way. We thought of it as job protection for the 'tribe'. It was simply good management practice, as everyone who had read Peter Drucker or Kenichi Ohmae knew, to use common parts from our company wide parts bin. The people who make the components wanted to build the same thing all day long, whether it's a resistor, a capacitor, a coil, or a custom mask microprocessor (apparently they also read Ohmae). As an example, we had one part, a Motorola 6805 micro controller in DIP (dual inline package), the centipede looking things you may have seen years ago when someone spoke of IC chips. Hitachi came in as a licensed second source on the 6805, and we saw enough demand for the part, as well as reduced single source risk, so we committed to take 500,000 of these processors per year in the 80's and 90's.At that volume level we could get this 6805 part for ~ $0.95 to $1.05 each (there was a Yen band currency hedge for Hitachi, and Motorola did the same with their Malay production). When we used this part with a different software mask, the new order would take 18 weeks from the time we transmiited our mask ( about 1.5 K of code for the ROM of the part, it was an 8 bit machine with ~ 0.1 K of RAM ) until we started to get production quantity deliveries - maybe 5 or 10 thousand parts per shipment.

If we wanted to ramp up production quickly, we could order the same part in an EPROM (electrically programmable read only memory ) version. This meant that each part was individually loaded with our code by a person sitting at a bench with some circuitry and some fixtures. We could do it this way, but the price was 10 to 12 dollars per part for ~500 pieces, and up to $30 or $40 each for < 100 pieces. There is an old rule-of-thumb in electronics that the bill of material (sum of all the parts cost) should approximate the retail price times five, e.g. a $100 kit of parts should cost about $500 at retail. We need to pay for the labor of production line people, accounting people, shipping, engineering, the light bill, the heat, maintenance, the auditors to figure the property tax, the withholding tax, the income tax, and earnings or losses to report to investors, even the grumpy guy in the corner office who shouldered bunches of risk when he gave this product the go-head yet still had to keep things moving forward and keep most of the group happy most of the time. They all have this habit of eating, and so on, plus the company needs something left over for a rainy day, when we have a stinker product, or a virus showed up, or to invest in the tooling needed for the next product, or to simply finance inventory on our slow moving products, and so on. The people who distribute that product far and wide with stores and employees, etc., all have the same pressure, and in the time of the virus, the distribution person had very few products that were moving off the shelves. He quickly determined that the cost burden of rent, utilities, payroll, taxes should all be allocated to these web cam widgets. It literally is either that, or lay off employees or simply board up the shop and go out of business.

Pull up the calculator on your computer. Figure the cost price increases of that nature for a unique PC board, some custom tooled case parts of molded plastic, a custom video processing part, a lens and CCD to fit inside your case and so on.

It's easy to see how a product can go from 70 to more than 200 dollars very rapidly for rapid production ramp ups. The opportunist rushing in to make an 'off brand' product has to pay large premiums to get delivery on parts, and he generally buys in lower quantity. He also doesn't generally have lots of experience in making a good version of the produt. They're just copies of the known maker, done by people who have near zero experience with the circuits and how to produce them to get the best performance. As someone who was with the company whose product was getting knocked-off there were many times we could at least laugh because the copiers had dutifully reproduced even the mistakes we had made.

The acknowledged maker, like Logitech, usually schedules production runs for every 30, 45, 60 days and loads a lot of boxes into inventory in a warehouse. The 'muscle memory' of the people on the production line gets better when they do the same movements repetitively, so let's have them run this product for days on end until market demand says switch to another product as inventories on it are running low. Some may call it oppressive, but you also benefit from better quality of products with this sort of build schedule. This is a human wiring factor that operates in much the same way you making fewer typing mistakes when you become accustomed to the keyboard you're using. The people who have been in the same business for a long time usually have some tricks in the design and the build process which they've learned with experience, and are not apparent to even a smart engineer just starting down the road of building these devices. Muscle memory of the 'spark chasers' you might call it.

Expedited service commands a premium.

So back to our price question and our advice. Is this price gouging? Our answer is that 'experts' who say yea and nay in these matters are much like those who have been birthed of a royal womb - people who make decisions for us, give us little or no say in the matter, are those to whom the normal rules and circumstances do not apply. We see more benefits in electing our rulers, and in making our own choices about which products to buy and at which prices. If we need one of these things quickly to go to school or go to work, there is very little choice, we weren't taught to expect perpetual nirvana, and there is certainly no magic wand the price expert can wave to solve the problem.If we wait the time proven 12 to 18 weeks for the factory to ramp up production and the distribution sector to normalize we can avoid the panic shift pricing. But we need jobs, our companies need to accomplish things under stress, just like those people making those web cams. We could buy a used, ex-school kid Chromebook like the ones we were obtaining nerly a year go for $60 or $70 each. They function, but they have cameras, microphones and speakers which are definitely SD quality. The catch now is that those things have nearly doubled in price on eBay. A higher end laptop could give you a better picture, but during the shutdown you couldn't even get into a retailer for a hands on session to test that theory. You've probably already made what you perceived to be the best of many worse choices. Who are we or anyone else to question it now. We simply know that good quality web cams are once again becoming available. If you are less than thrilled with the way you look on an SD web cam, or frustrated with an off brand web cam that claims HD properties, but produces a washed out or ultra contrast picture, it's time to plan. The remote working and learning environment we adopted in shutdown will probably be with us for some time to come. As we've written elsewhere, IBM and others have made plans to keep much of their workforce at home. They're even planning to let the leases expire on half of their rented office space. That indicates to us that this remote conference phenomena will be around for some time to come, and we will do well by allocating resources to these electronic conveyances while knowing our expenses for tires, batteries, automobiles, and gasoline should be far less in the future. The laws of supply and demand always work, even in the Soviet gulags those laws worked. We're not exempt, nor are we terribly damaged by a spate of second rate video.

Some thoughts on meeting software

Working to improve, or circumvent, our WiFi radios

Our WiFi home network has become a hinderance.